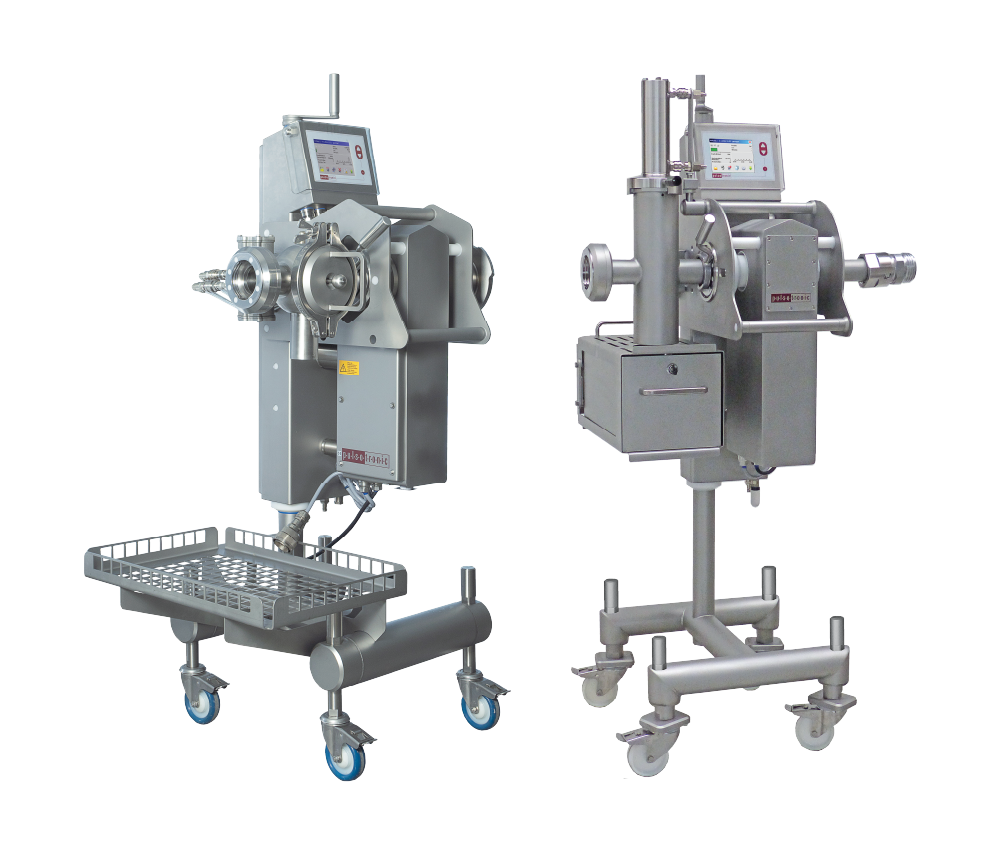

Pipe Detector-Inflex

The metal detector is designed and constructed for use with stuffer ore filling machines.

Sausage and meatloaf or other high-viscosity products such as dough, marzipan, and soups can be checked with these metal detectors.

The high-strength product tubes keep pressures up to max. 55 bar (rotary slide valve 40 bar). The connection is made with RD80 screwed or original stuffer typical connections.

The Inflex65-3 is height adjustable and mobile. It is suitable for all common fillers. Has an option available with linking gear or different automatic reject systems.

Function

The pumped product is scanned from the metal detector and checked for metallic foreign bodies.

The detected metal is rejected by the rejection system (optional) or the filler is stopped for manual removal. This depends on the application.

Specific Characteristics

- speed-controlled, high-capacity engine

- Protection class IP69K of all components

- Hygiene design of all components

- slight height adjustment via spindle

- M-Pulse2 control and operation

- 4 quadrant display/vibration filter

- Product clustering/vibration filter

- Hinge suspension of the rejection system /tool-free installation

Other Pipe Detectors

Pipe Detector - INLINE

M-Pulse Inline Devices is used for the detection of fluid products and commodities on metallic contamination.