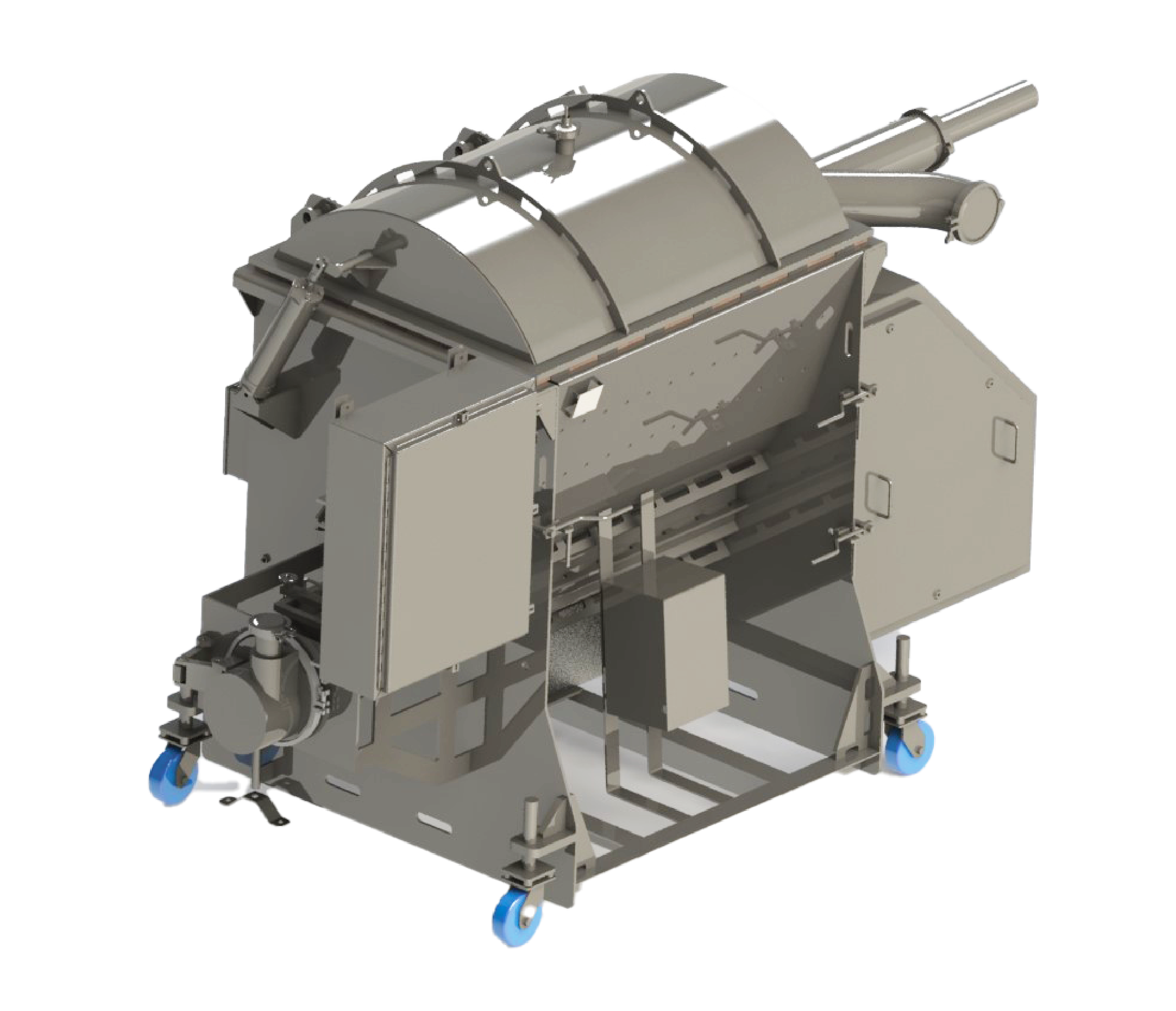

Continuous Vacuum Stuffer

The Continuous Vacuum Stuffer is a specialized piece of equipment used in the food processing industry, particularly in the handling and preparation of protein-based products. Its primary function is to remove air from the product during processing, which is crucial for maintaining product quality and consistency. The removal of air helps prevent the formation of air pockets, which can cause defects in texture and appearance, and can also contribute to spoilage by providing an environment for bacterial growth.

Application

This machine is designed to gently portion and extrude proteins, making it ideal for a wide range of applications. It is particularly effective for sectioned and formed products such as ham, turkey, roast beef, and various poultry items. By using the Vacuum Stuffer, producers can ensure that their products have a uniform shape and size, which is important for both aesthetic and cooking consistency. This uniformity is achieved without compromising the integrity of the product, as the vacuum stuffer’s gentle handling preserves the natural texture and moisture content of the proteins.

Efficiency

The Continuous Vacuum Stuffer is versatile enough to be used with a variety of emulsions, including those used in pet food manufacturing. In this context, the machine helps to create a homogenous blend of ingredients, ensuring that each portion contains the right balance of nutrients and flavors. The precise portioning capabilities of the vacuum stuffer also allow for efficient packaging, reducing waste and improving overall production efficiency.

Overall, the Vacuum Stuffer is a critical tool in the food processing industry, offering reliable performance for a wide range of protein and emulsion-based products. Its ability to enhance product quality, consistency, and safety makes it a valuable asset for manufacturers aiming to meet high standards in both human and pet food markets.

Standard Options

- Variable speed electric drive system

- Stainless steel control panel with manual and automatic mode settings

- Pneumatically operated product load valve

- Quick disconnect feed pump (no tools required for disassembly)

- Vacuum stuffing capacity ‐ up to 30,000lbs per hour (varies by product)

- Vacuum system with filtration canister

- Removable stainless steel side panels for easy access

- All interior welds ground smooth

- USDA acceptable and CE units available

Additional Options

- Polished interior

- 5 H.P. Vacuum system–Includes “Y” loading valve