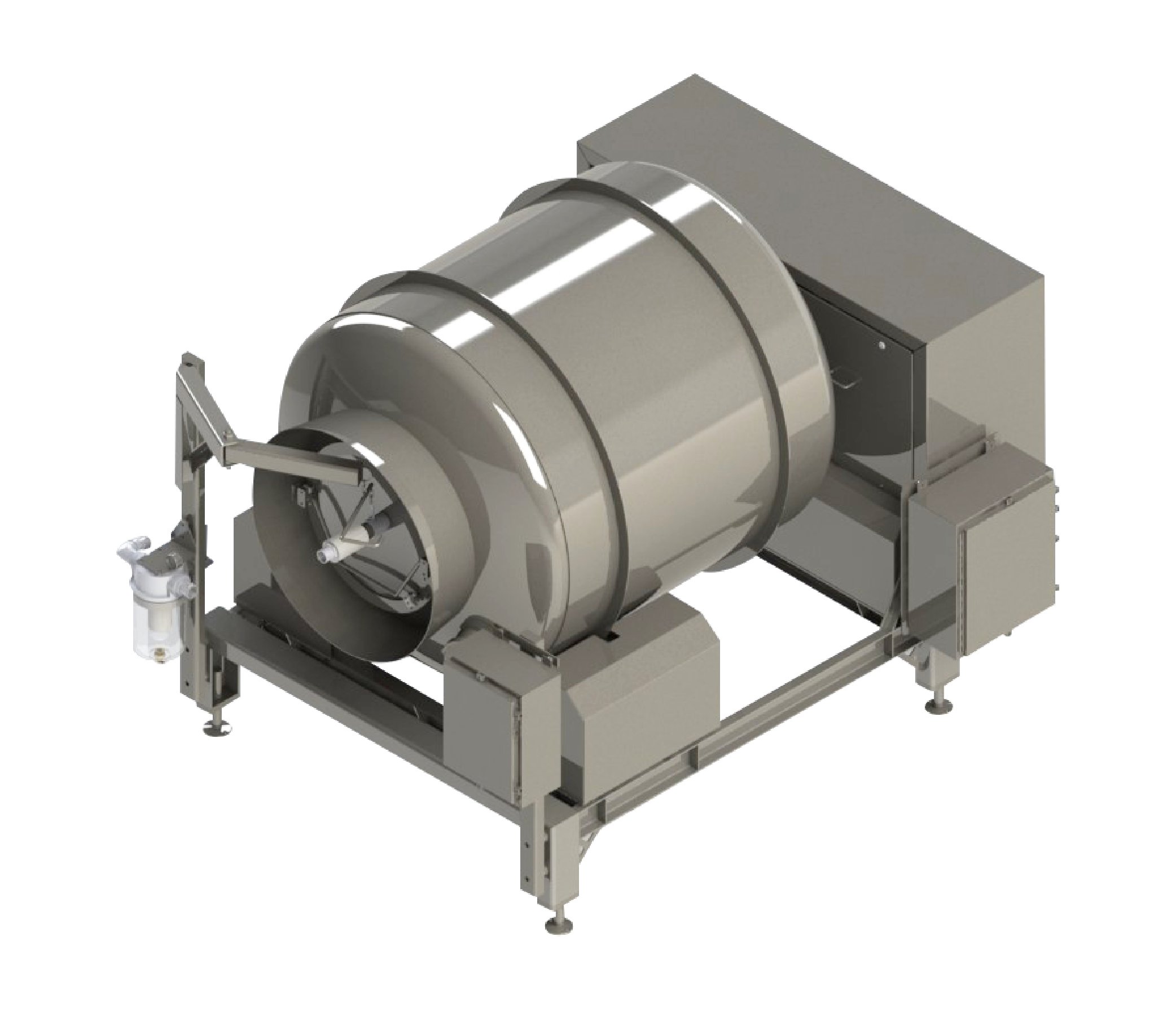

Horizontal Tumbler

The Horizontal Tumbler is a specialized piece of equipment designed to enhance the quality and flavor of various meat products. By utilizing a vacuum environment, this tumbler is ideal for processing a wide range of meats, including ham, turkey, chicken breasts, wings, roast beef, and even seafood. The vacuum mechanism plays a crucial role in the tumbling process, as it helps to infuse marinades, brines, and seasonings more deeply and evenly into the meat. This results in a product that is not only more flavorful but also tender and succulent.

Advantages

One of the primary advantages of using the Horizontal Tumbler is its ability to shorten the marinating time significantly. Traditional marinating methods often require several hours or even days to achieve the desired flavor penetration. In contrast, the vacuum environment in the tumbler accelerates this process, allowing for quicker preparation times without compromising quality. This efficiency is particularly beneficial for food processing facilities that require consistent results in a shorter timeframe.

Efficiency

The Horizontal Tumbler can improve the texture and juiciness of the meat. The tumbling action massages the meat, breaking down muscle fibers and enhancing its natural tenderness. This is especially useful for tougher cuts of meat that would otherwise require longer cooking times to become tender. For seafood, the gentle tumbling ensures that delicate items like fish fillets and shrimp are evenly coated and infused with flavor without being damaged.

Overall, the Horizontal Tumbler is a versatile and efficient tool for anyone looking to elevate the quality of their meat and seafood products. Whether used for marinating, tenderizing, or seasoning, this equipment offers a reliable solution for achieving consistently delicious results.

Standard Options

- Variable speed electric drive (2-12rpm)

- Drive & Vacuum system enclosed in Stainless Steel Cabinet

- Programmable control panel with manual & automatic settings

- 10″ diameter inspection port

- Glass Bead blasted to a satin finish

- Standard Capacities 500lbs – 10,000lbs

Additional Options

- Glycol cooling jackets

- CO2 injection

- Vacuum loading

- Polished interior