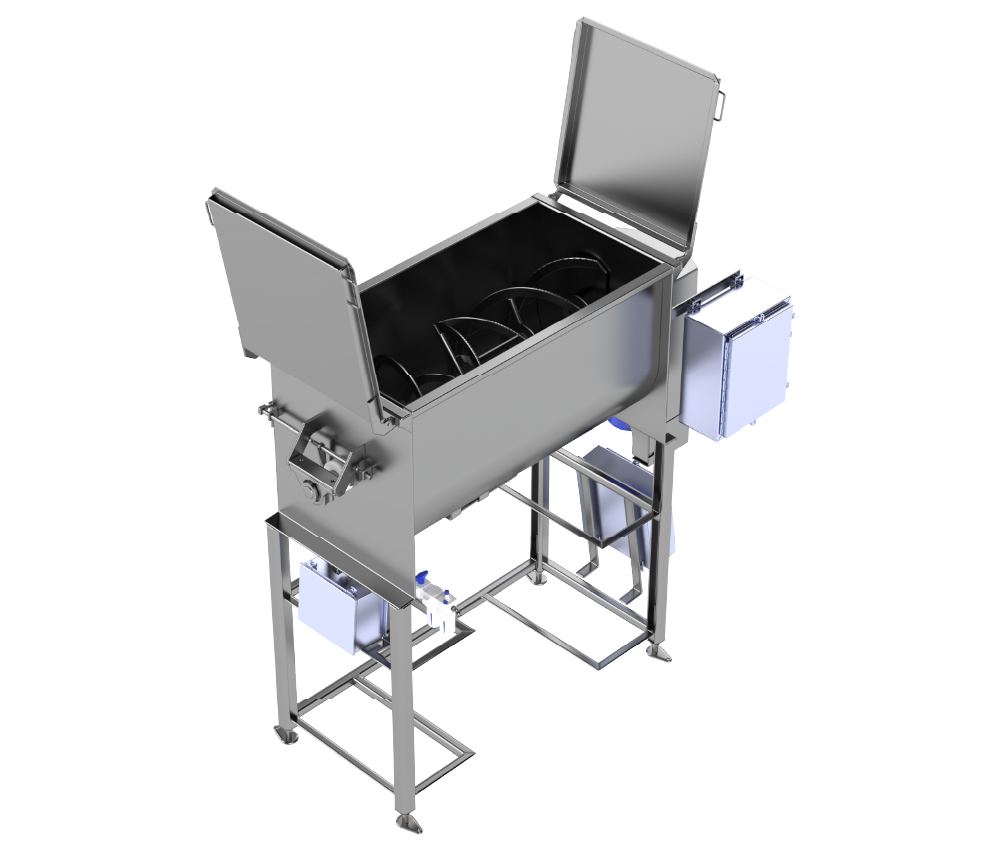

Dry Ingredient Mixer

The Dry Ingredient Mixer is a versatile piece of equipment specifically designed for the food industry, offering a reliable solution for the consistent and efficient blending of dry ingredients. This mixer is engineered to meet the highest standards of sanitary design, making it an ideal choice for applications where hygiene and cleanliness are paramount.

Key Feature

One of the key features of the Dry Ingredient Mixer is its robust construction, which ensures durability and longevity, even under continuous operation. The mixer is equipped with advanced mixing mechanisms that provide thorough and uniform mixing, ensuring that all ingredients are evenly distributed throughout the batch. This level of consistency is crucial in the food industry, where precise ingredient distribution can significantly impact the quality and safety of the final product.

Cleaning & Sanitizing

In addition to its excellent mixing capabilities, the Dry Ingredient Mixer is designed with ease of cleaning in mind. The mixer’s components are made from materials that are resistant to corrosion and easy to sanitize, which helps prevent contamination and ensures compliance with stringent food safety regulations. The design also allows for quick disassembly, further facilitating the cleaning process and minimizing downtime between production runs.

Overall, the Dry Ingredient Mixer is a reliable and efficient choice for food manufacturers seeking a high-quality mixing solution. Its combination of robust performance, sanitary design, and ease of maintenance makes it a valuable asset in any food production facility.

Standard Options

- SOLID agitator shaft with dual ribbons

- Manually operated slide valve for bottom discharge

- Quick Release Shaft Seal to help facilitate cleaning

- Full cover with safety interlock

- All interior welds ground smooth

- Electrical disconnect

- Mounted on SS adjustable legs or SS casters

- Two hand “no-tie down” on controls

- Standard capacities: 10 CU FT–100 CU FT

Additional Options

- PLC controls

- Polished interior