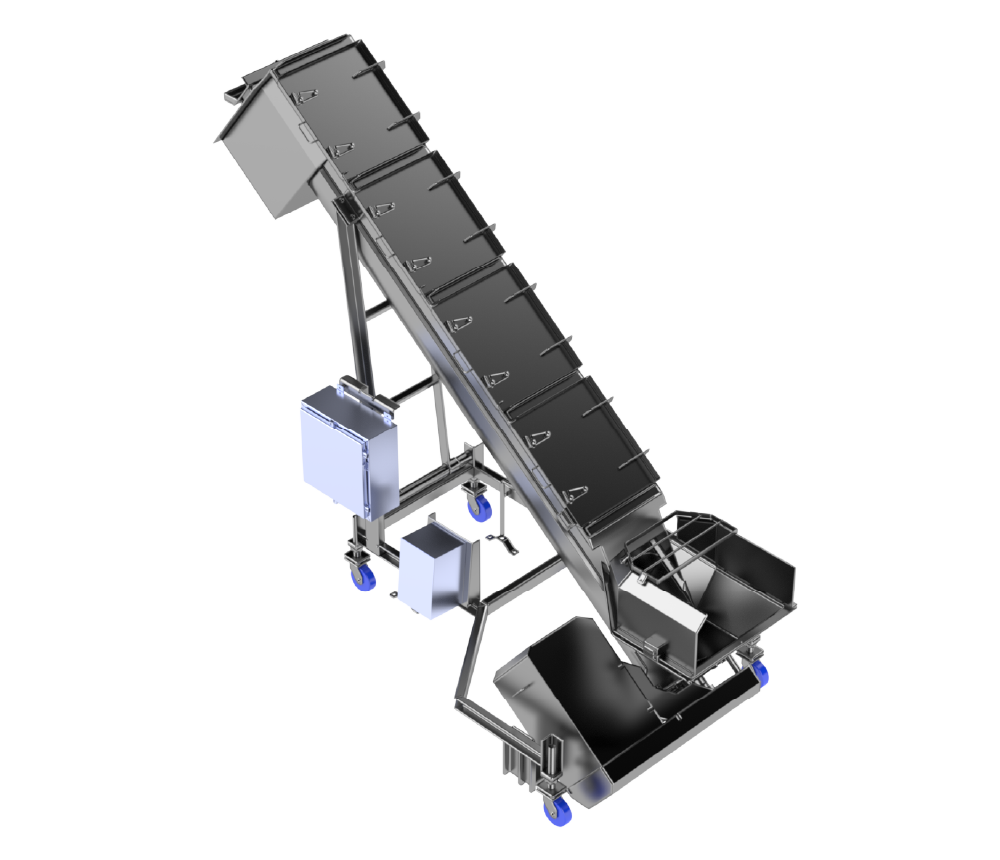

Screw Conveyor

The Screw Conveyor is a specialized system meticulously designed to address the specific needs of industries like meat, poultry, and pet food processing. It is engineered to facilitate the hygienic transfer of products, ensuring that both raw materials and finished goods are moved efficiently and safely between locations. This conveyor system stands out for its focus on maintaining the highest levels of cleanliness and product integrity, which are crucial in industries where sanitary conditions are paramount.

Cleaning & Sanitizing

Adhering to stringent sanitary standards, the Screw Conveyor is constructed with materials and design features that prevent contamination and ease cleaning processes. This is essential in environments where the risk of

cross-contamination must be minimized, and where product integrity directly impacts consumer safety and brand reputation. The conveyor’s design ensures that every aspect, from the screw mechanism to the conveyor housing, is optimized for easy sanitation and minimal residue retention.

Efficiency

The reliability of the Screw Conveyor makes it a valuable asset in production lines that require consistent and dependable operation. Its ability to handle a variety of products, including delicate raw materials and more robust finished goods, without compromising on hygiene standards, positions it as an essential tool in the supply chain. By maintaining strict adherence to food safety regulations and hygiene protocols, the Screw Conveyor supports manufacturers in delivering high-quality products that meet industry standards and consumer expectations.

Standard Options

- Quick-release shaft seals

- Hinged covers with locks

- Mounted on casters or fixed placement

- All interior welds ground smooth

- USDA accepted

Additional Options

- 2 OR 3 point power pivot

- Lowering cylinders to facilitate cleaning

- Different screw diameters and pitches

- Heavy duty flights (1/4”-1/2” thick)

- Staircase mounted to the unit for sanitation

- VFD